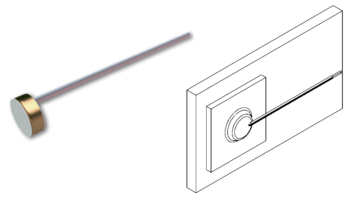

Measuring the temperature of flat surfaces can be difficult with a cylindrical probe. To improve the surface area contact and sensor response time, BAPI recommends using our Surface Sensor. The design of the sensor allows for an easy “peel and stick” installation with thermally conductive adhesive. Adding the included foam insulation to the back of the sensor helps insulate it from ambient air for an accurate surface temperature measurement.

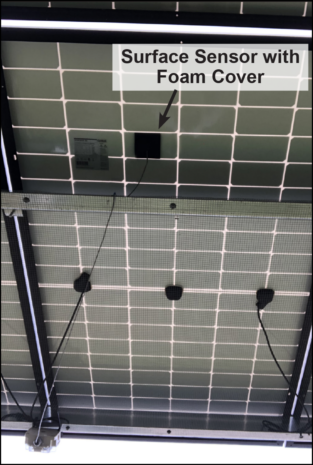

Using the Surface Sensor on Photovoltaic Solar Arrays

Accurate and reliable solar panel surface temperature measurements are important for assessing Photovoltaic (PV) performance. The surface temperature is used as an estimate of the temperature at the semiconductor junction inside the panel. This temperature, combined with other electrical and atmospheric data, can be used to model the expected power output from the solar array.

A good practice is to install BAPI’s surface sensor near the middle of the most central panel and to secure the sensor’s lead wires to the panel as a strain relief to prevent the wires from pulling on the sensor. The panel surface should be clean and dry before attaching the sensor. The provided isopropyl alcohol wipes work well for cleaning the surface before applying the sensor. The included foam insulation should be added to the back of the sensor to insulate it from the ambient air and ensure the sensor output represents the panel temperature.

The effect of temperature on the power output of solar arrays (the temperature coefficient of power) is a negative value, meaning a lower temperature results in a higher power output. An accurate temperature measurement is very important for modeling the expected output. A poorly executed surface measurement usually results in a reading that is lower than the actual temperature. The result is an “over forecast” of the power output. As an example, monocrystalline and polycrystalline silicon – two of the most common materials used in solar arrays – have a temperature coefficient of power of about -0.46% per °C. That means a surface temperature reading 7°C below the actual value will result in an over forcast of expected power output by about 3.22% (-7°C x -0.46% = 3.22%). This is a significant error for large arrays.

To reduce signal degradation on long wire runs, a 4 to 20 mA output should be used to eliminate any error caused by the resistance of the cable itself.

Before placing the sensor on the desired surface, clean the surface by using the provided isopropyl prep pad and then let the area dry. If the surface is not cleaned, the adhesive will not reach full bonding capability.

Once the surface is dry, pull the release sheet from the thermal adhesive on the sensor and apply the sensor to the desired area firmly. Once the sensor is applied, slide the EPDM (Ethylene Propylene Diene Monomer) foam down the wire and firmly place over the sensor. Be sure to remove large air gaps under the foam.

EPDM is a closed cell foam designed for higher temperatures and resistance to ozone and oxidation. Using this foam helps insulate the sensor to ensure its reading represents the panel temperature. If the foam is not installed, the ambient air can significantly affect the reading of the sensor.

Before placing the sensor on the desired surface, clean the surface by using the provided isopropyl prep pad and then let the area dry. If the surface is not cleaned, the adhesive will not reach full bonding capability.

Installation Best Practices

Once the surface is dry, pull the release sheet from the thermal adhesive on the sensor and apply the sensor to the desired area firmly. Once the sensor is applied, slide the EPDM (Ethylene Propylene Diene Monomer) foam down the wire and firmly place over the sensor. Be sure to remove large air gaps under the foam.

EPDM is a closed cell foam designed for higher temperatures and resistance to ozone and oxidation. Using this foam helps insulate the sensor to ensure its reading represents the panel temperature. If the foam is not installed, the ambient air can significantly affect the reading of the sensor.

For more information about the Weather Shade, contact a BAPI key account specialist at +1-608-735-4800.