This document describes how noise is created on sensor cables by 24 VAC power, how this noise can adversely affect the HVAC controller’s operation, and how to prevent the AC power noise.

Noise Caused by AC Power

Most modern HVAC control systems have 24 VAC available, and most of BAPI’s products can run on 24 VAC, yet BAPI recommends powering them with DC voltage. Why?

Twisted wire cables have high wire-to-wire capacitance. Capacitors block DC voltage, but allow a little bit of AC voltage to couple from wire to wire. A portion of the 60 Hz 24VAC running through one pair of wires in a multi-wire cable will combine with the normal signals on all the other wires in the cable. This will happen no matter whose sensor is used.

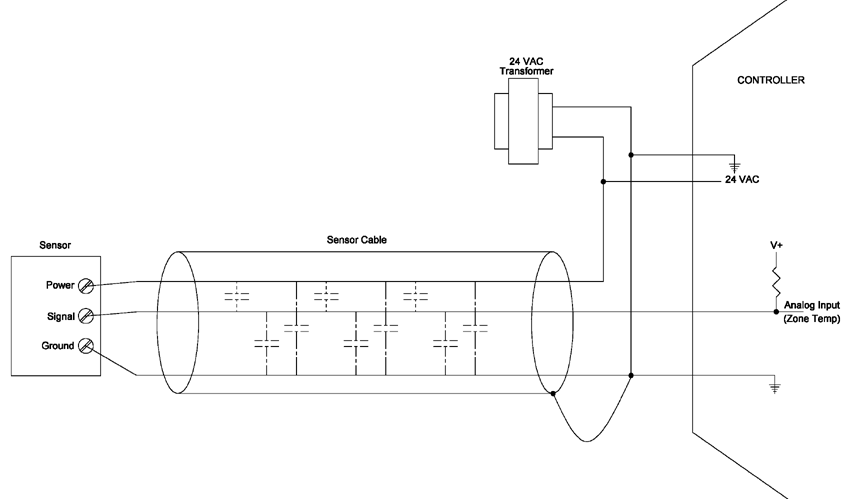

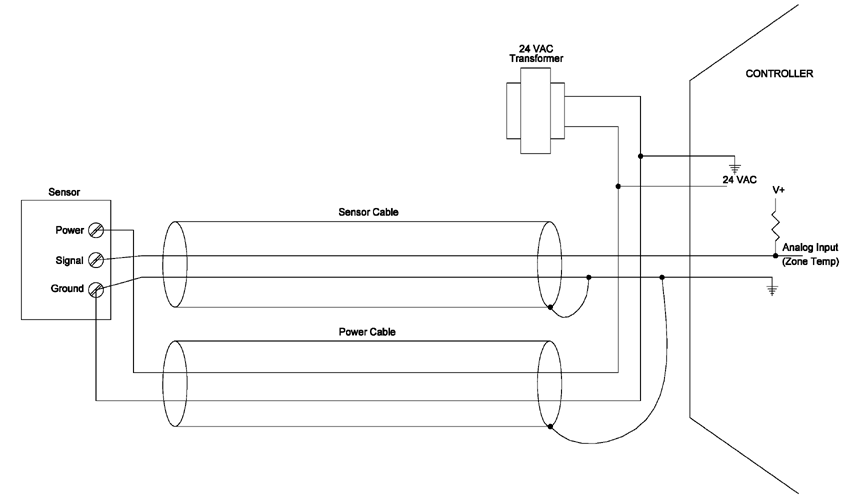

Figure 1 shows a typical zone sensor application powered by 24VAC. (The powered device can be any type of transmitter not just a zone sensor) The capacitors drawn with dashed lines inside the sensor cable represent the wire-to-wire capacitance. The copper wires, inside their insulation, running in parallel with the other wires in the cable, form the capacitors.

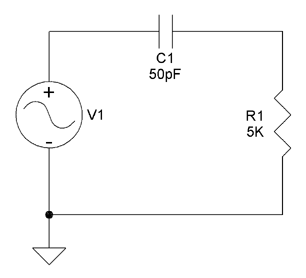

Figure 2 shows a simplified version of Figure 1. Figure 2 is an equivalent circuit of the coupling phenomena and is used for detailed circuit analysis. V1 is the 24VAC transformer from Figure 1, C1 is the wire-to-wire capacitance per foot and R1 represents the sensor cable’s resistance and the 10K thermistor sensor in parallel with the controller’s input circuit. The voltage at the junction of the capacitor and the resistor is the signal sent to the controller’s zone temperature measurement circuit. With the values shown in Figure 2, the 60Hz noise voltage at the junction is ± 0.0032 volts per foot. For a nominal 25-foot sensor wire length the noise is ± 0.080 volts.

The Effects of AC Power Noise on the HVAC system

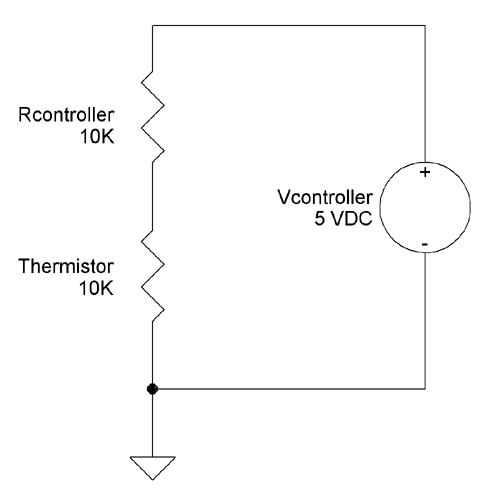

Figure 3 shows a typical controller’s zone temperature input circuit. The voltage at the junction of the two resistors is the signal value representing the zone temperature. At 77°F, the voltage is 2.5VDC. The ± 0.080 volt noise signal is added to the 2.5VDC temperature signal. Sixty times a second the temperature signal changes from 2.58 volts to 2.42 volts and back again. The voltage change is the same as if the thermistor changed resistance from 9,380 Ohms to 10,661 Ohms.

A 10K-2 thermistor’s temperature at 9,380 Ohms is 79.7°F and at 10,661 Ohms is 74.4°F. Your controller’s zone temperature circuit is changing from 74.4°F to 79.7°F sixty times a second. If the sensor wire length is longer than 25 feet, the perceived temperature swing is greater.

Most controllers do not make zone temperature measurements often enough to follow the 60 HZ noise smoothly. Tests with representative controllers show a zone temperature fluctuation of +/- 0.5°F around 77°F. Every couple of minutes, the sampling interval lines up with a minimum or a maximum noise spike and a non-existent zone temperature measurement change of 3°F shows up in your controller, therefore the controller thinks the temperature in the room is changing back and forth rapidly.

HVAC controls systems often have a built-in “deadband,” a small temperature region above and below the setpoint temperature in which no control action occurs. This deadband keeps control machinery such as valves and actuators from being adjusted many times per second, or oscillating, and thus wearing out prematurely. The maximum and minimum temperature spikes described in the above paragraph exceed the deadband, therefore the controller may drive the mechanical equipment into an oscillation, causing it to wear out.

Methods of Eliminating AC Power Noise

If you run the 24VAC in a separate, shielded cable, the capacitance from the 24VAC wires to the signal wires is so low it is effectively ZERO. No AC voltage combines with your sensor signals but you must run two separate cables. Make sure to connect the 24VAC power cable’s shield to a good building ground at the controller end as shown in Figure 4.

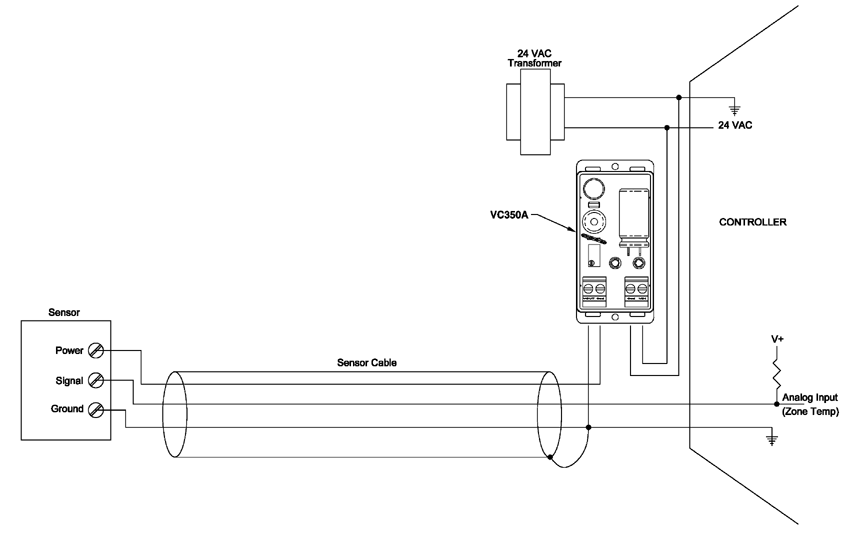

If you power the sensor with DC voltage, then there is no AC noise within the multi-wire cable to influence the temperature reading. But remember, the DC converter has to be mounted at the controller end of the wire, not at the sensor end, otherwise there will still be AC power within the multi-wire cable. See figure 5 for suggested wiring layout.

Either of the methods described here – running the AC in a separate shielded cable or converting the AC to DC power – will prevent the AC noise from influencing the sensor’s signal. But BAPI recommends converting the AC power to DC power because we feel it is easier and more economical to install a low cost voltage converter rather than making two cable runs.

If you have any questions, please call your BAPI representative.